This is why Hella worklights are more than worth

the money

11

Hella knows that in practical use,

worklights are exposed to harsh

conditions. Therefore, during development

and also during manufacture (!), all types

of worklight are specifi cally tested to meet

the high Hella quality demands.

To start with, there are two tests to

determine and check compliance with the

IP protective rating.

The splash-water test reveals how a

worklight withstands rain, splash water, silt

and the high-pressure cleaner. To do so,

the worklight is constantly sprayed

with water as if from a high-pressure

cleaner, in a closed chamber.

The purpose of the dust-protection

test is to test to what extent a worklight is

protected from the penetration of foreign

solid bodies, including dust. To do this,

the test sample is exposed for a certain

time, in a chamber, to a fl ow consisting of

an air/dust mixture.

There are then three further stages to this

tortuous testing.

Two-part heat test: Part 1 is

the 24-hour test. Over this period, the

worklight remains switched on constantly.

In the second part, the worklight is

subsequently exposed to a temperature

of 50°C for a period of one hour. A value

which can quickly be reached in summer

use.

Shake test and vibration test: Here,

the behaviour of the worklight during

driving is simulated. Worklights that pass

this test always illuminate correctly.

Fogging test: In the fogging test, Hella

tests how the worklight handles moisture

penetration. If the fogging disappears in a

specifi ed short unit of time, the worklight

is operating correctly.

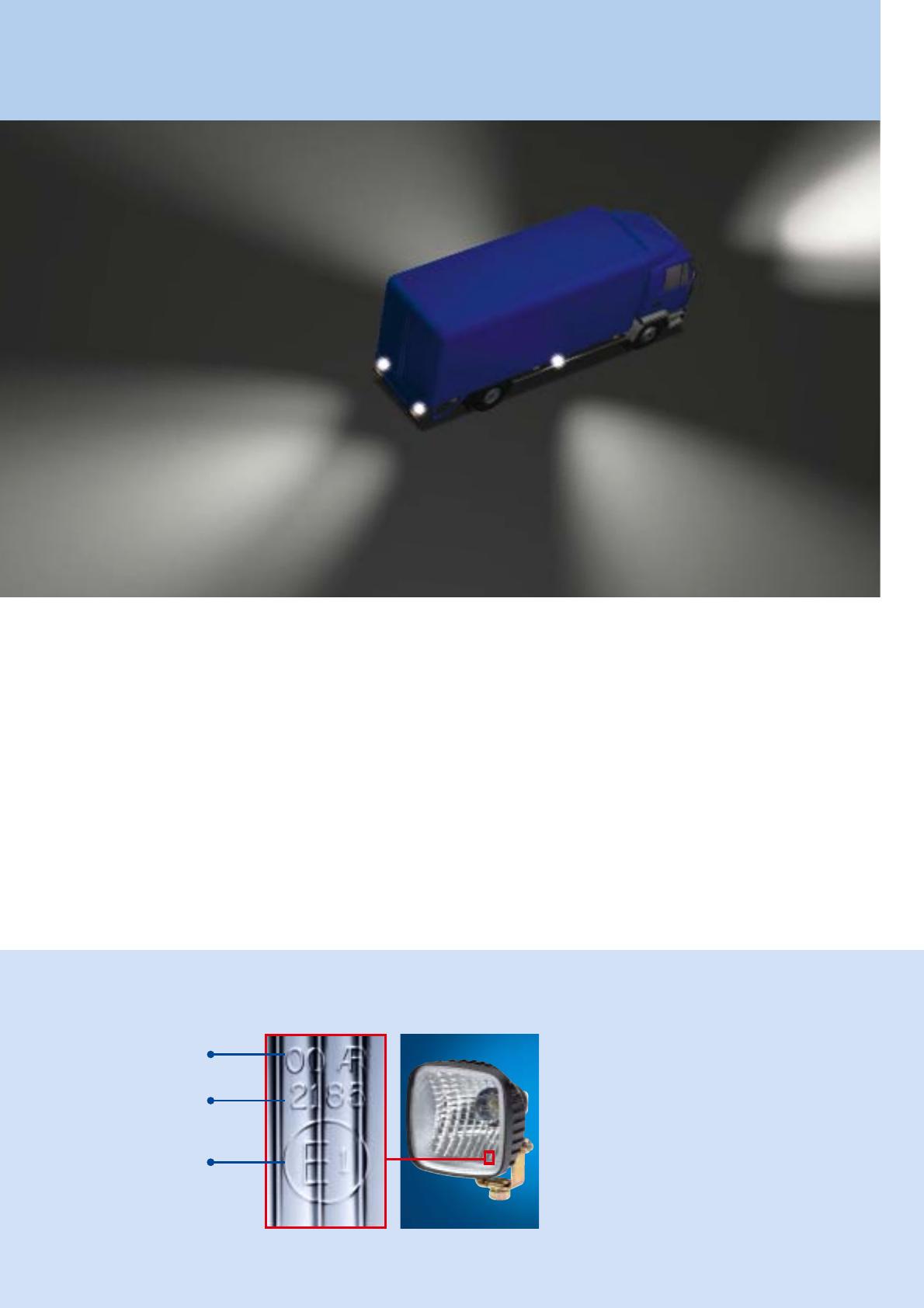

GGVSEB and IP protective

categories:

GGVSEB means hazardous-goods

directive for roads. Worklights so marked

are approved for mounting to

transportation equipment which meets the

regulations of the GGVSEB/ADR

B Rn 10251 and Rn 11251 for

electrical alignment.

IP protective categories provide known

standards when purchasing. How well is a

product protected from the environmental

infl uences Worklights are exposed to

e.g. dust and water? The IP protective

category states how resistant the

product is. The classes are determined in

accordance with DIN 40 050 Part 9.

In the case of Hella worklights, these

protective ratings are used:

Protective category IP 5K4K

Dust may only penetrate to such an extent

that function and safety are not impaired.

Water that sprays against the housing

from every direction under increased

pressure must not have any damaging

e ect; water pressure approx. 4 bar.

Protective category IP 5K9K

Dust may only penetrate to such an extent

that function and safety are not impaired.

Water that is directed against the housing

during high-pressure/steam-jet cleaning

must not have any damaging e ect; water

pressure approx. 80 bar.

Protective category IP 6K4K

Dust must not penetrate. Water that

sprays against the housing from every

direction under increased pressure must

not have any damaging e ect; water

pressure approx. 4 bar.

Protective category IP 6K7

Dust must not penetrate. Even in the

event of temporary submersion, no water

may penetrate.

Protective category IP 6K9K

Dust must not penetrate. Water that is

directed against the housing during high-

pressure/steam-jet cleaning must not

have any damaging e ect; water pressure

approx. 80 bar.