|

32

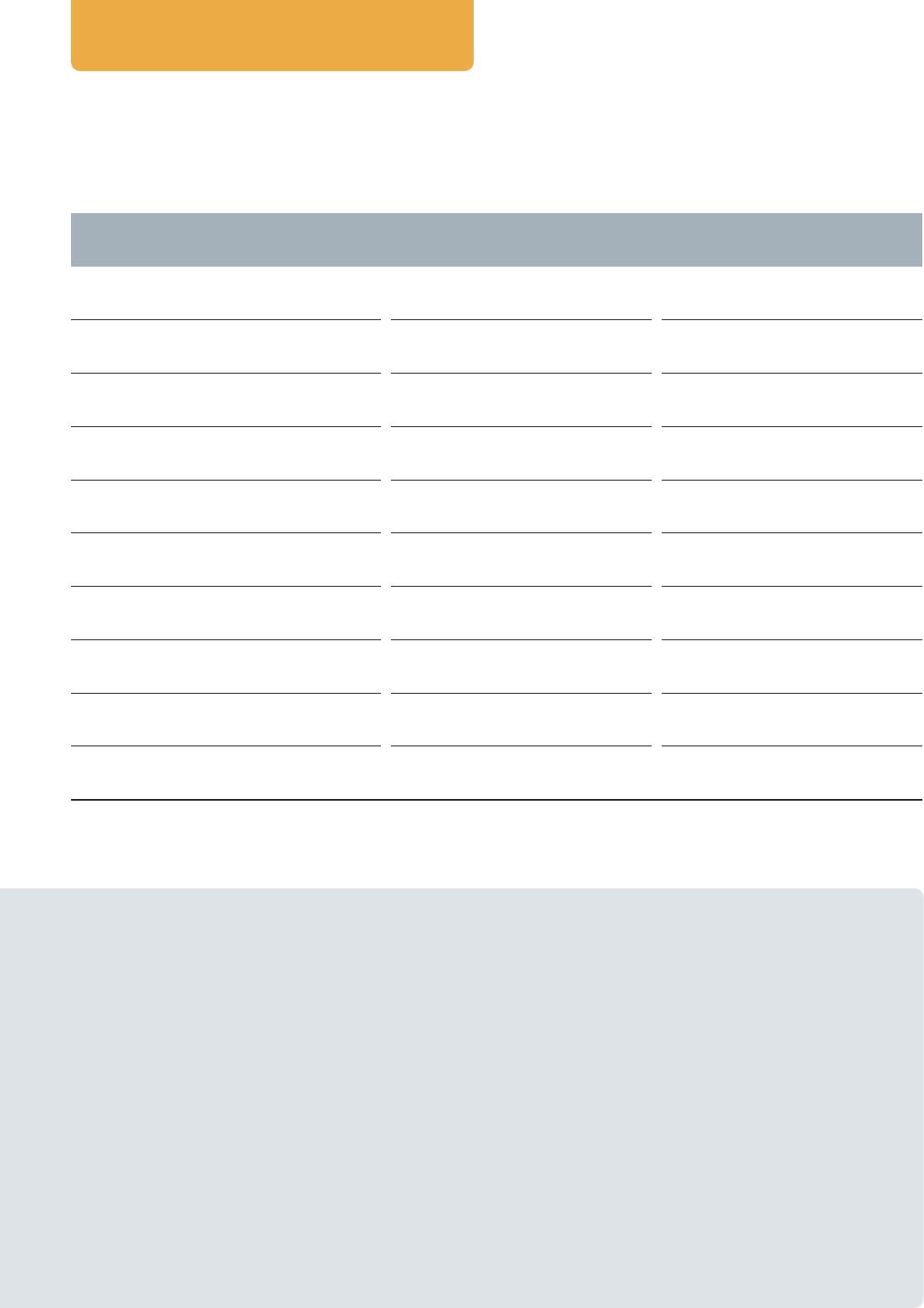

INTRODUCTION 2

A small component with a big history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

How HELLA checks and ensures quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

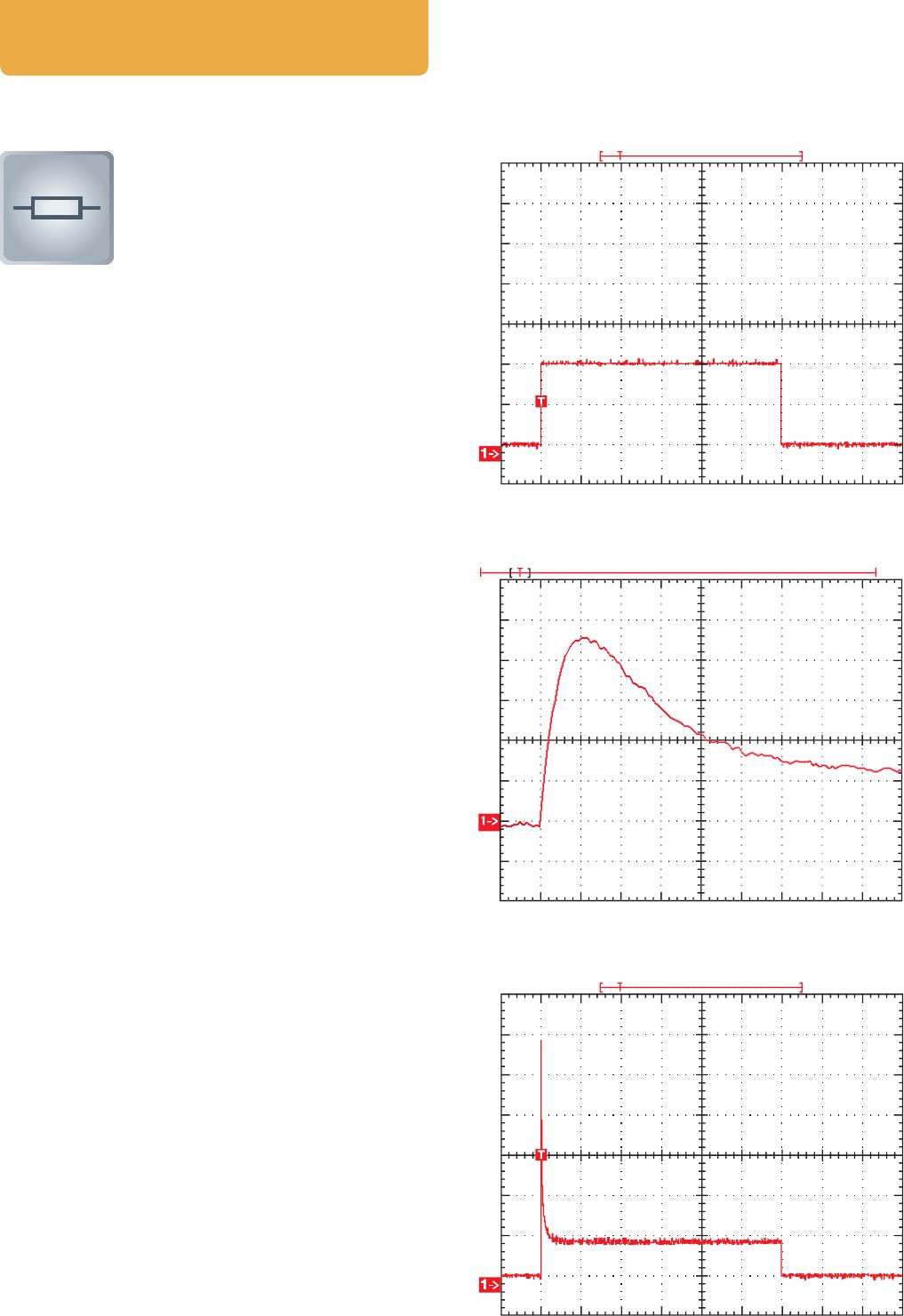

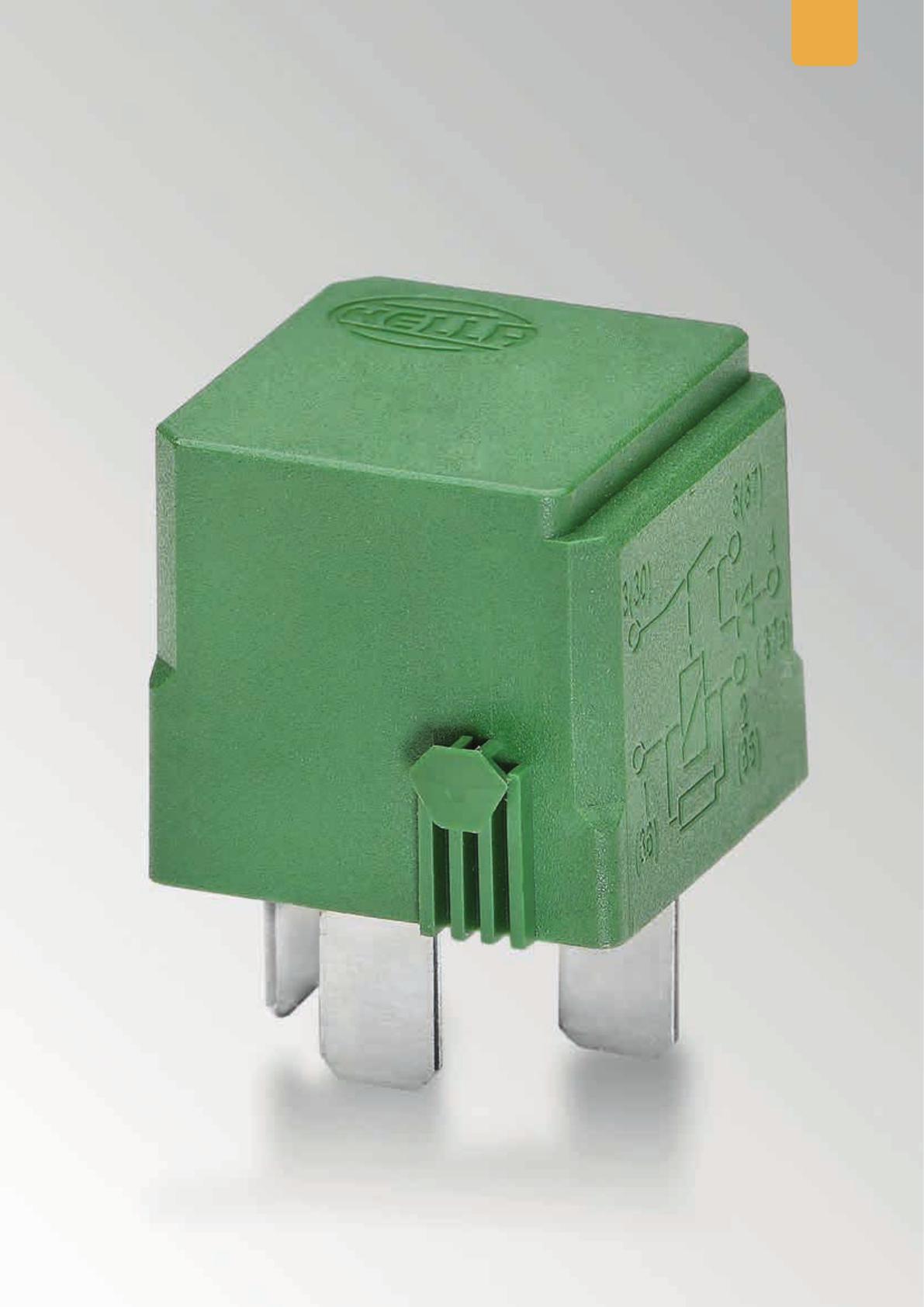

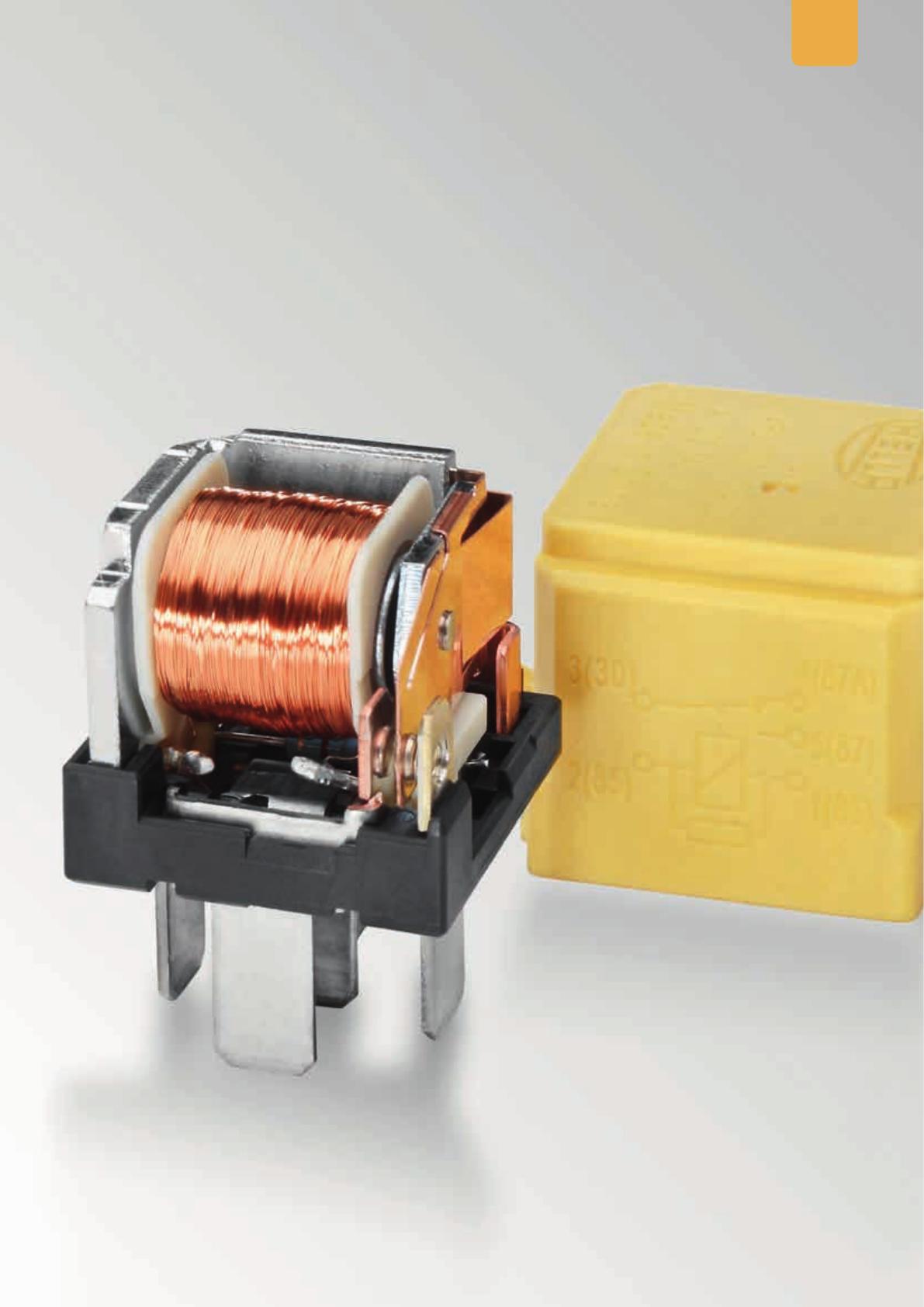

ELECTROMECHANICAL RELAYS 8

Explanation and uses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

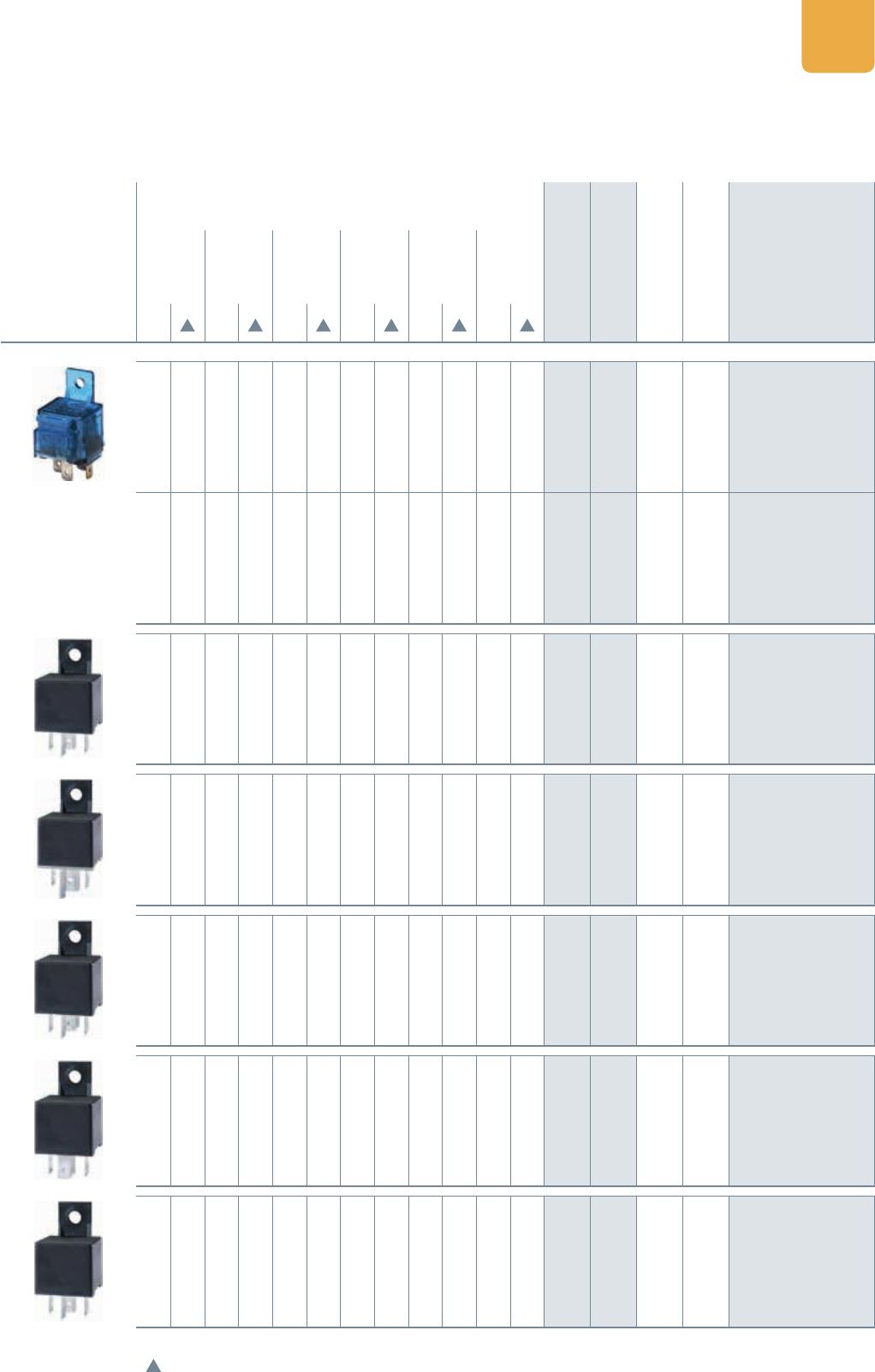

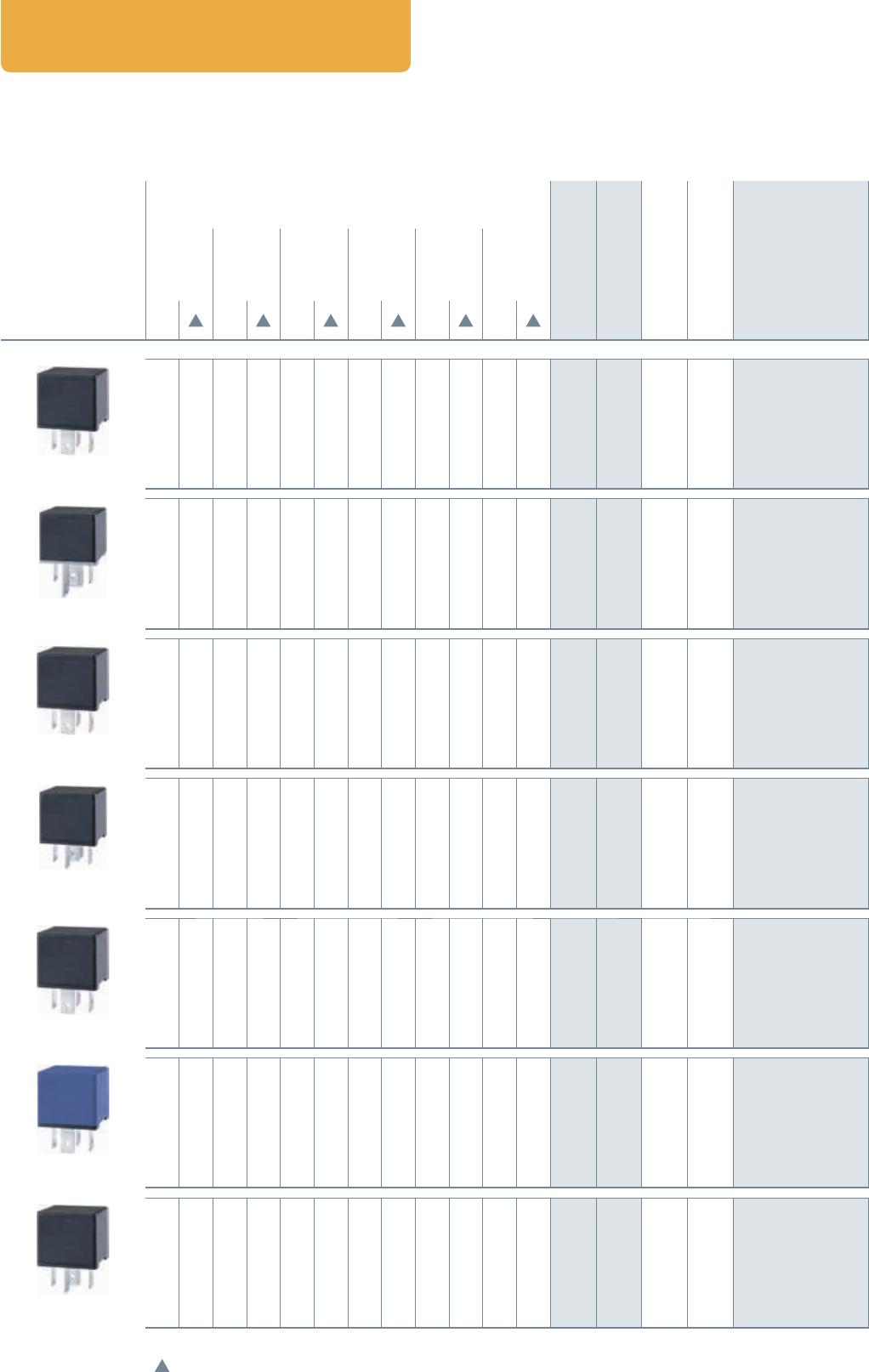

Relay types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Mini relay 12 V – make contact with holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Mini relay 12 V, make contact without holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Mini relay 12 V, change-over contact with holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Mini relay 12 V, make contact without holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Mini relay 24 V – make contact with holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Mini relay 24 V, make contact without holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Mini relay 24 V, change-over contact with holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Mini relay 24 V, make contact without holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

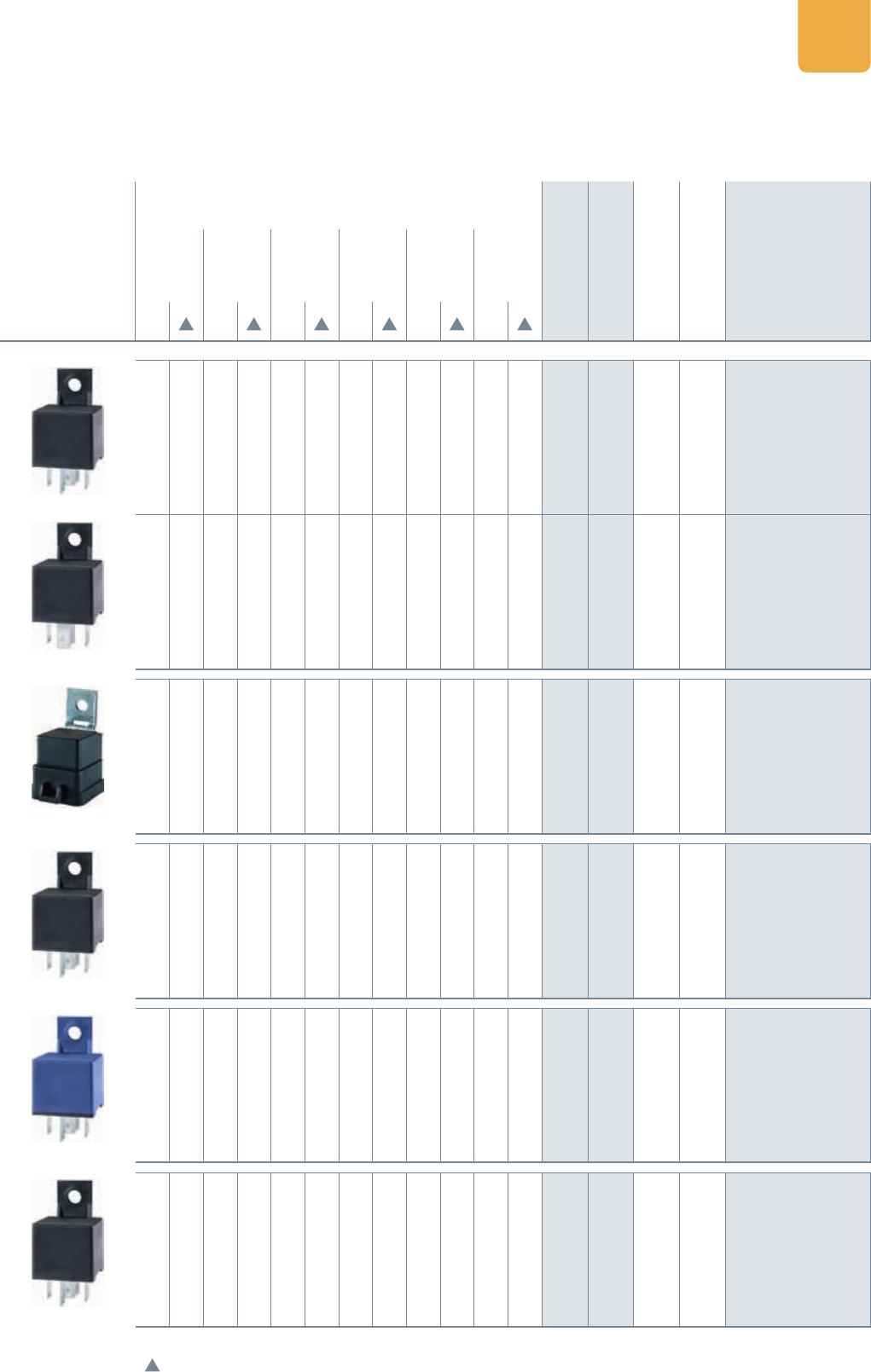

MICRO RELAY 22

Micro relay 12V, make contact without holder / change-over contact without holder . . . . . . . . . . 22

Micro relay 24V, change-over contact without holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

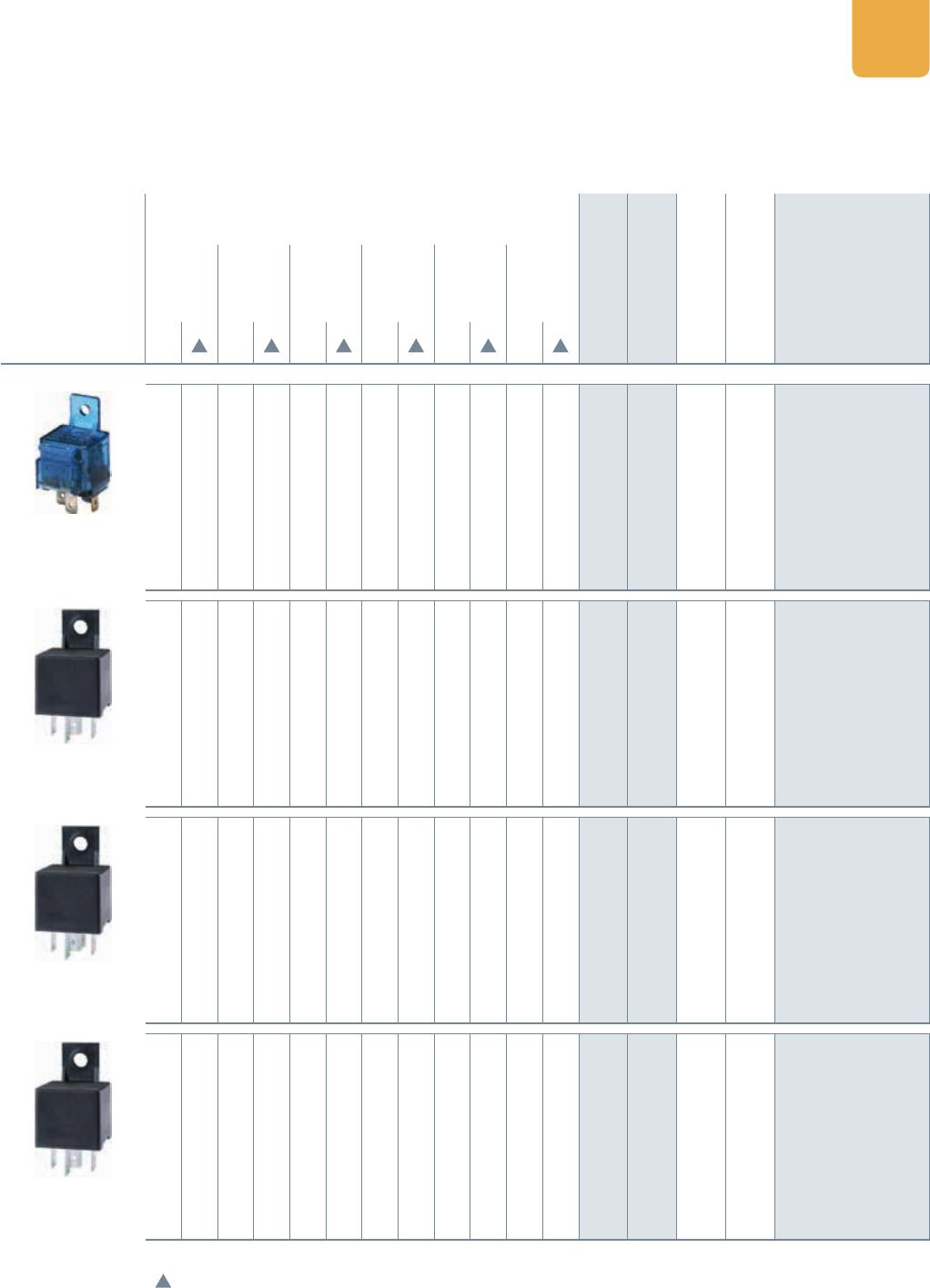

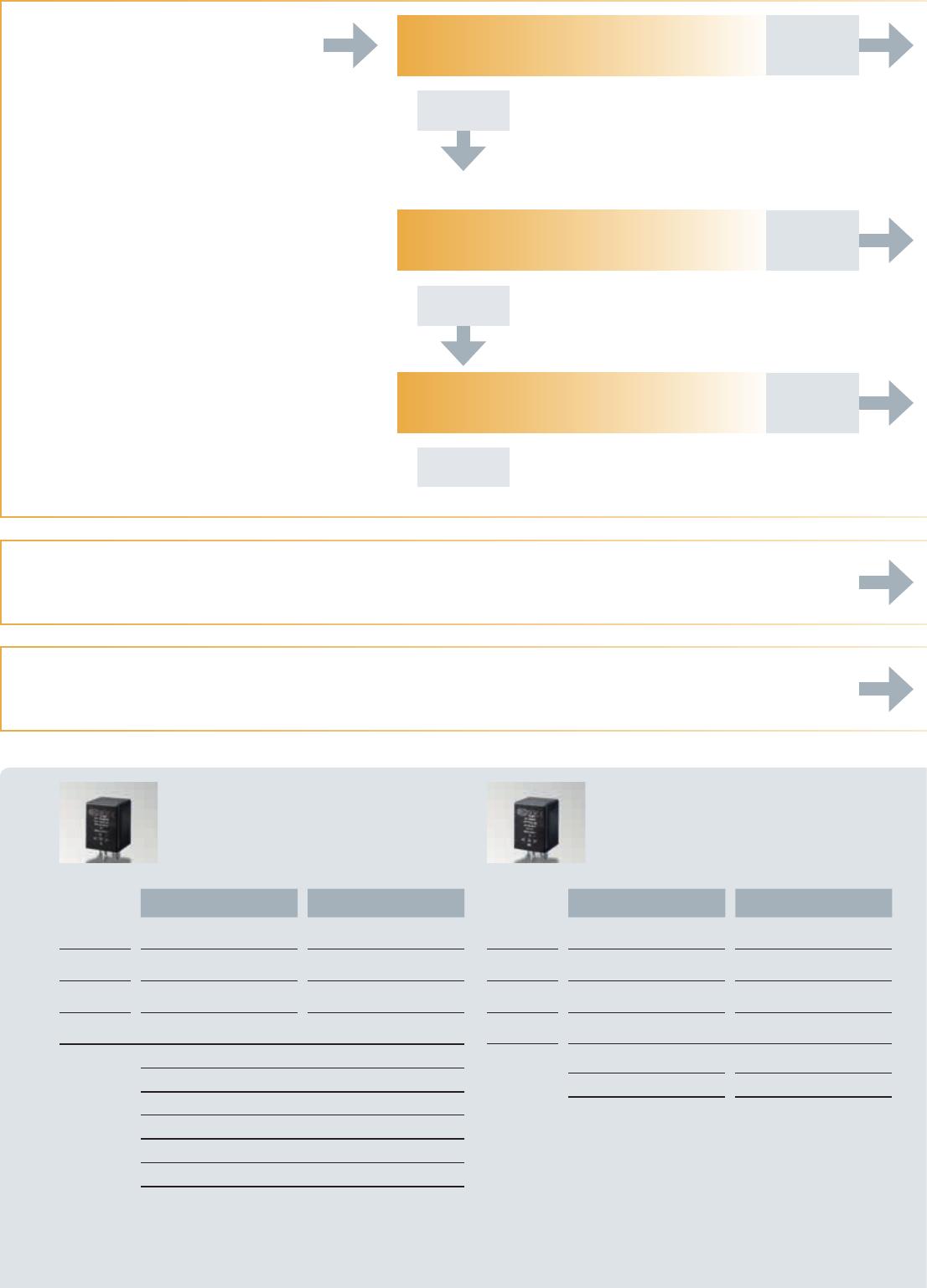

HIGHPOWER RELAY 24

High-power relay 12V, make contact with holder/without holder . . . . . . . . . . . . . . . . . . . . . . . . . . .24

High-power relay 24V, make contact with holder/without holder . . . . . . . . . . . . . . . . . . . . . . . . . . .25

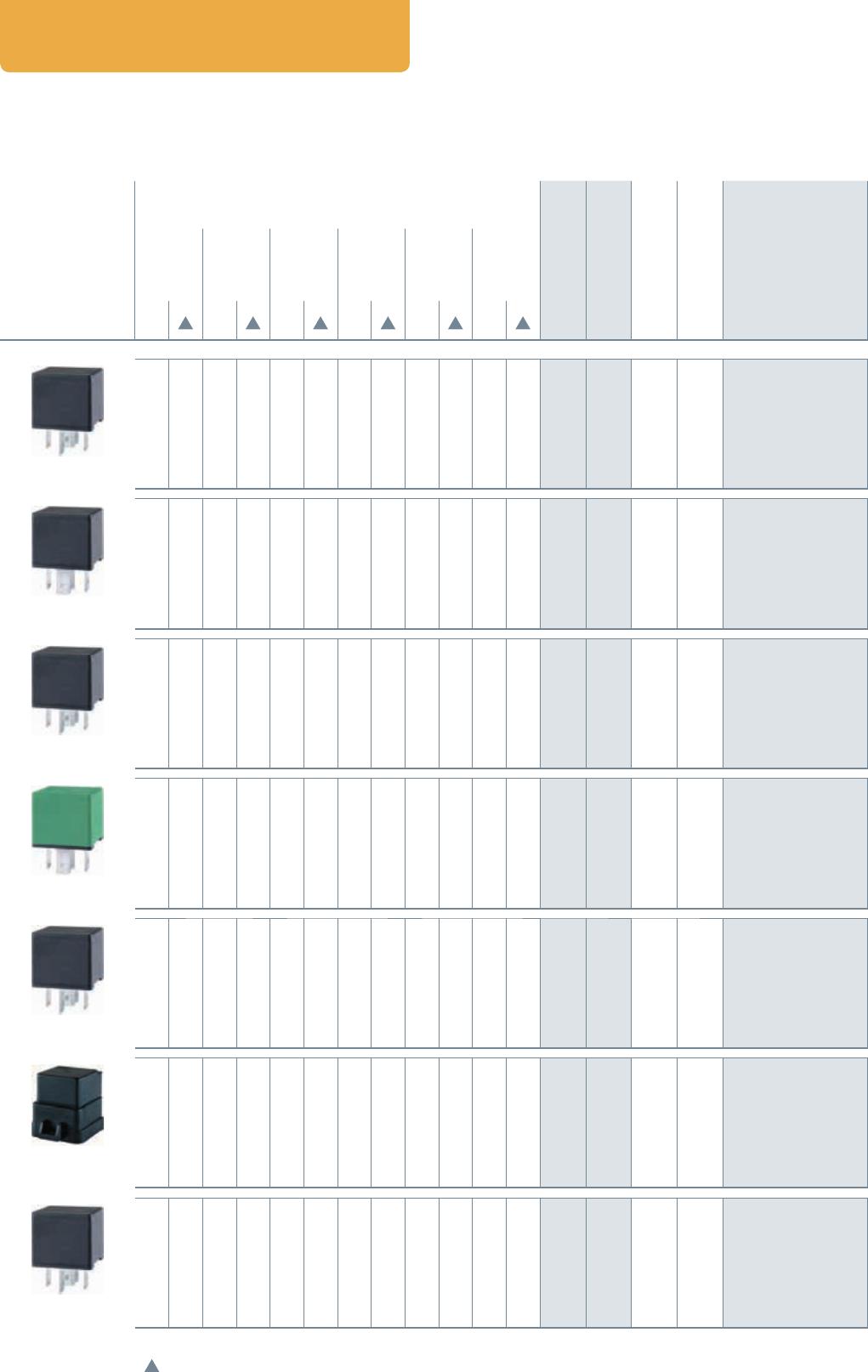

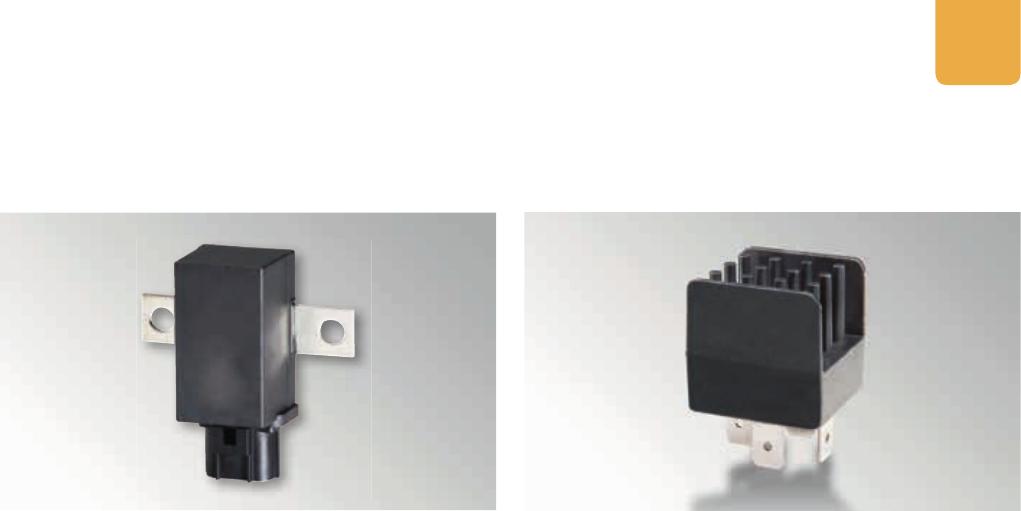

BATTERY DISCONNECT RELAY/SOLID STATE RELAY 26

Battery disconnect relay and solid state relay 12V, make contact . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Summary of battery disconnect and solid state relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

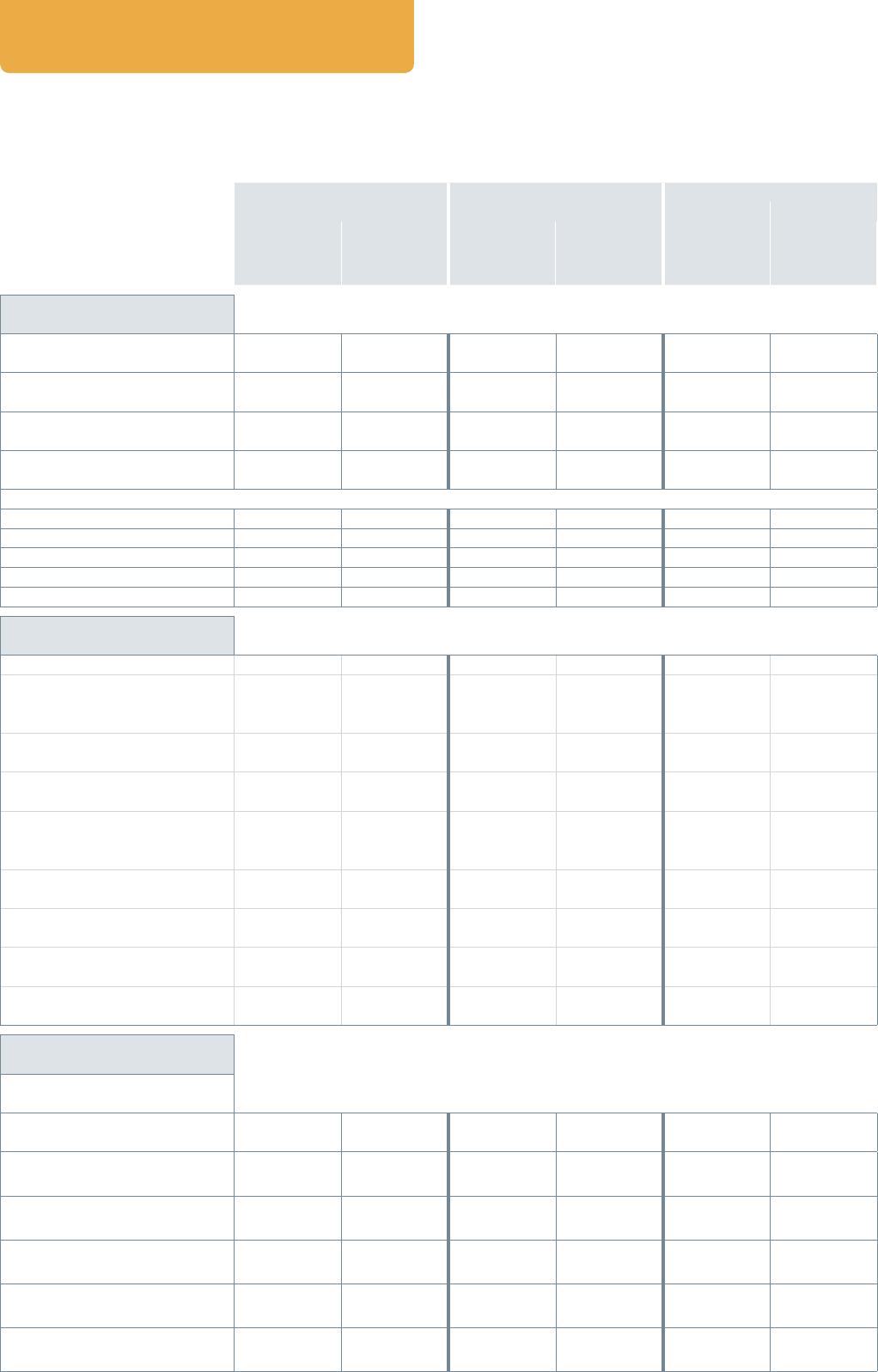

TECHNICAL DATA 28

Technical data of the relays – Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Climatic and mechanical tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

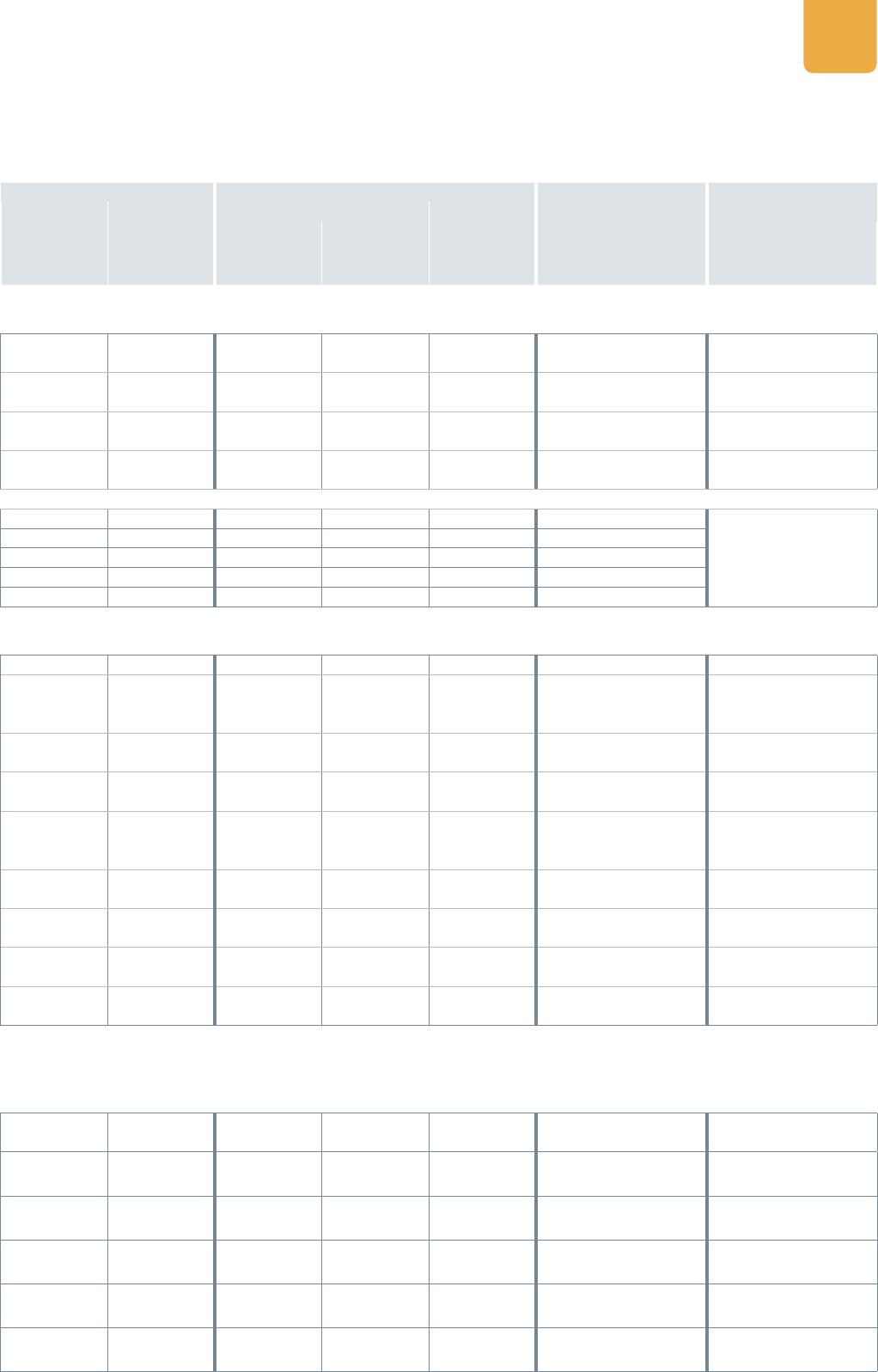

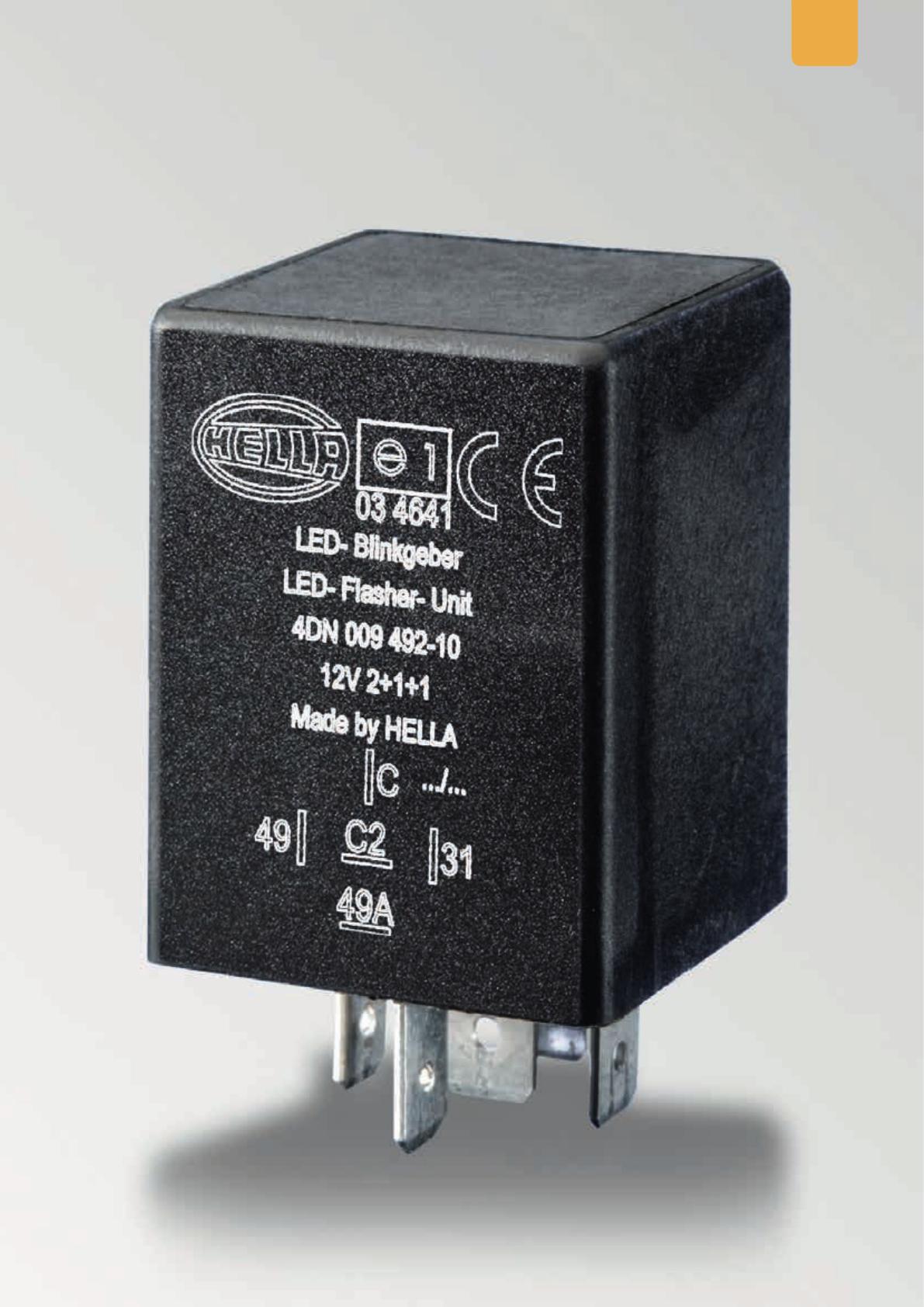

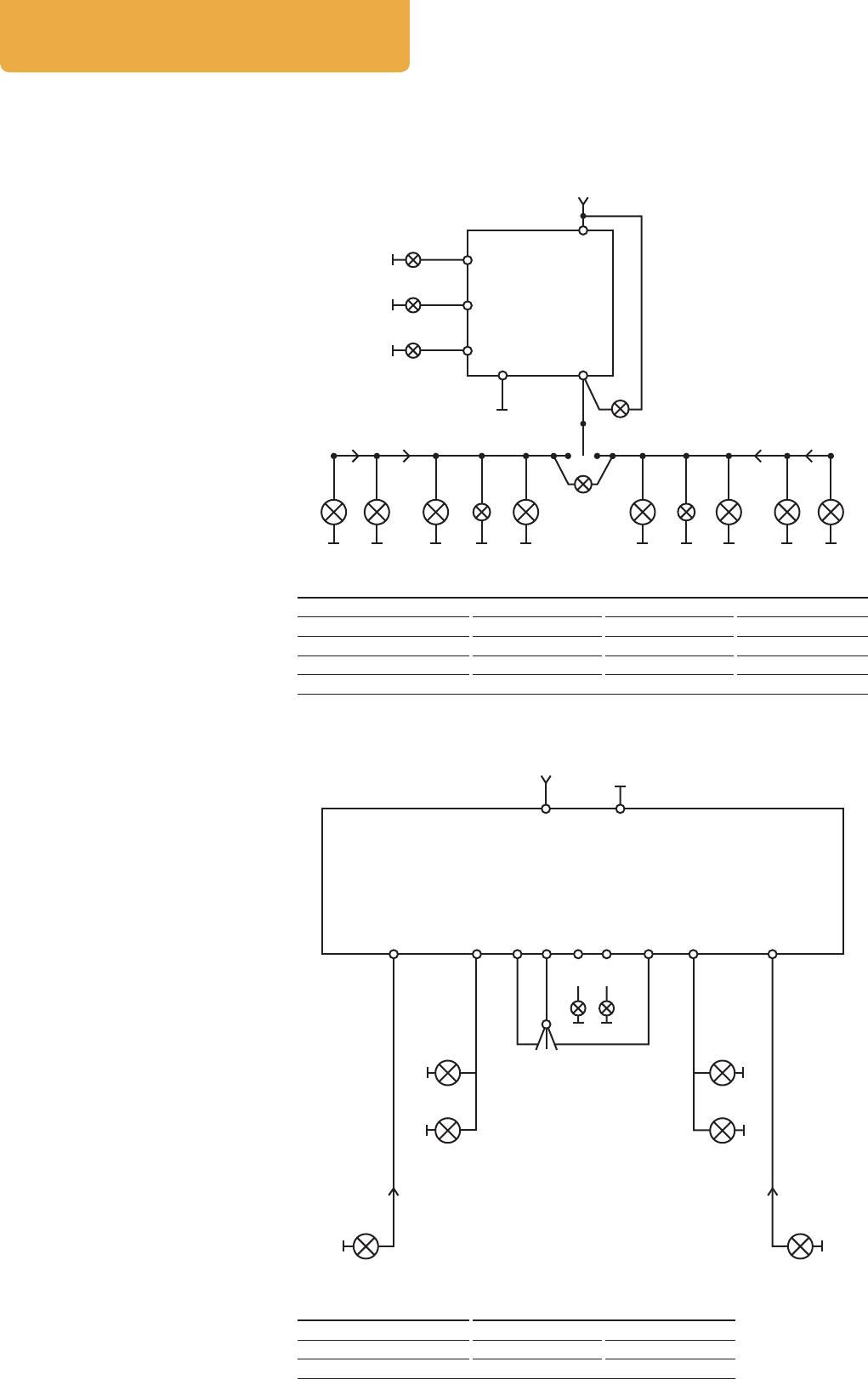

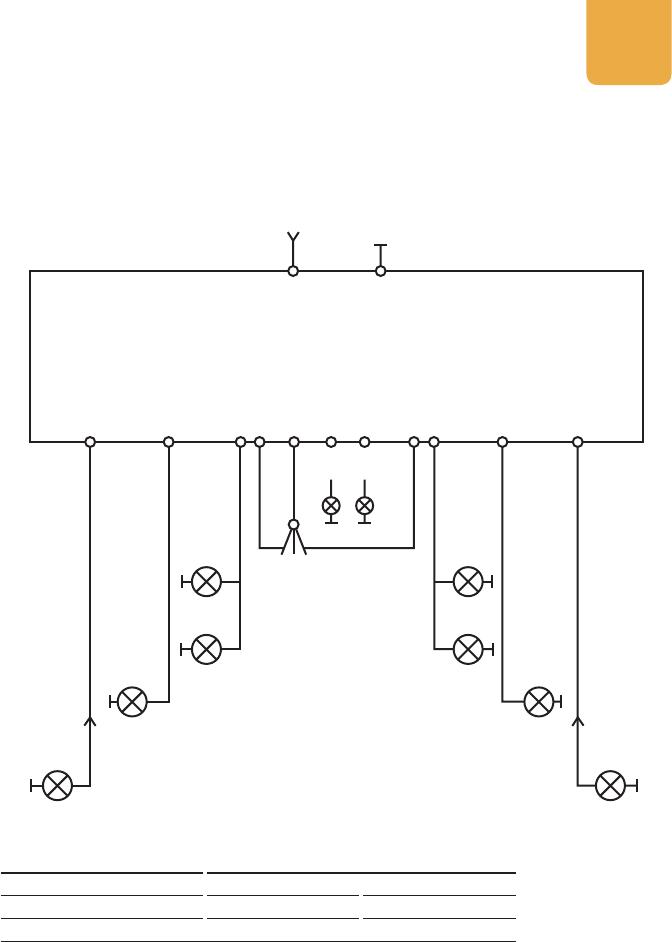

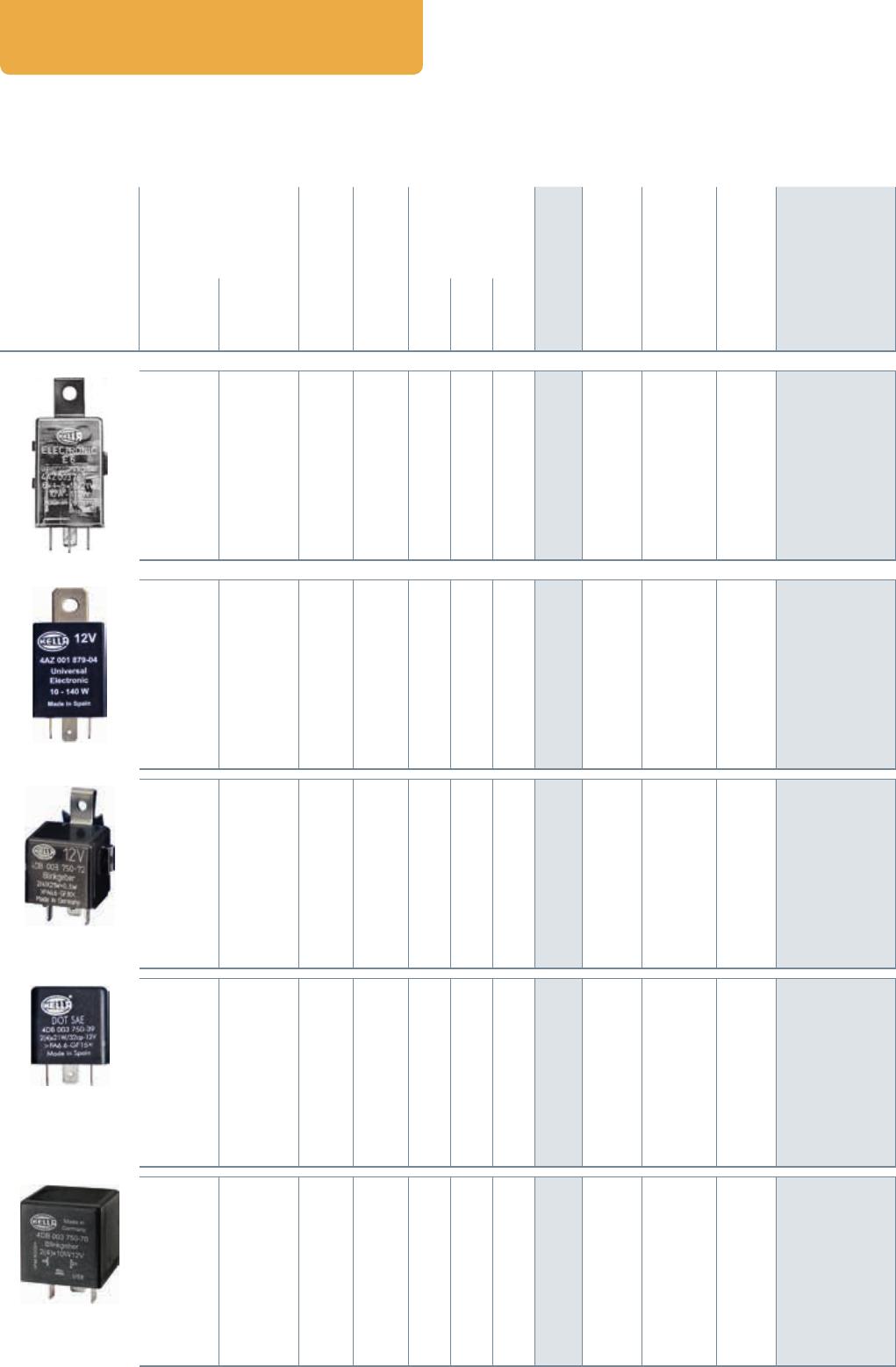

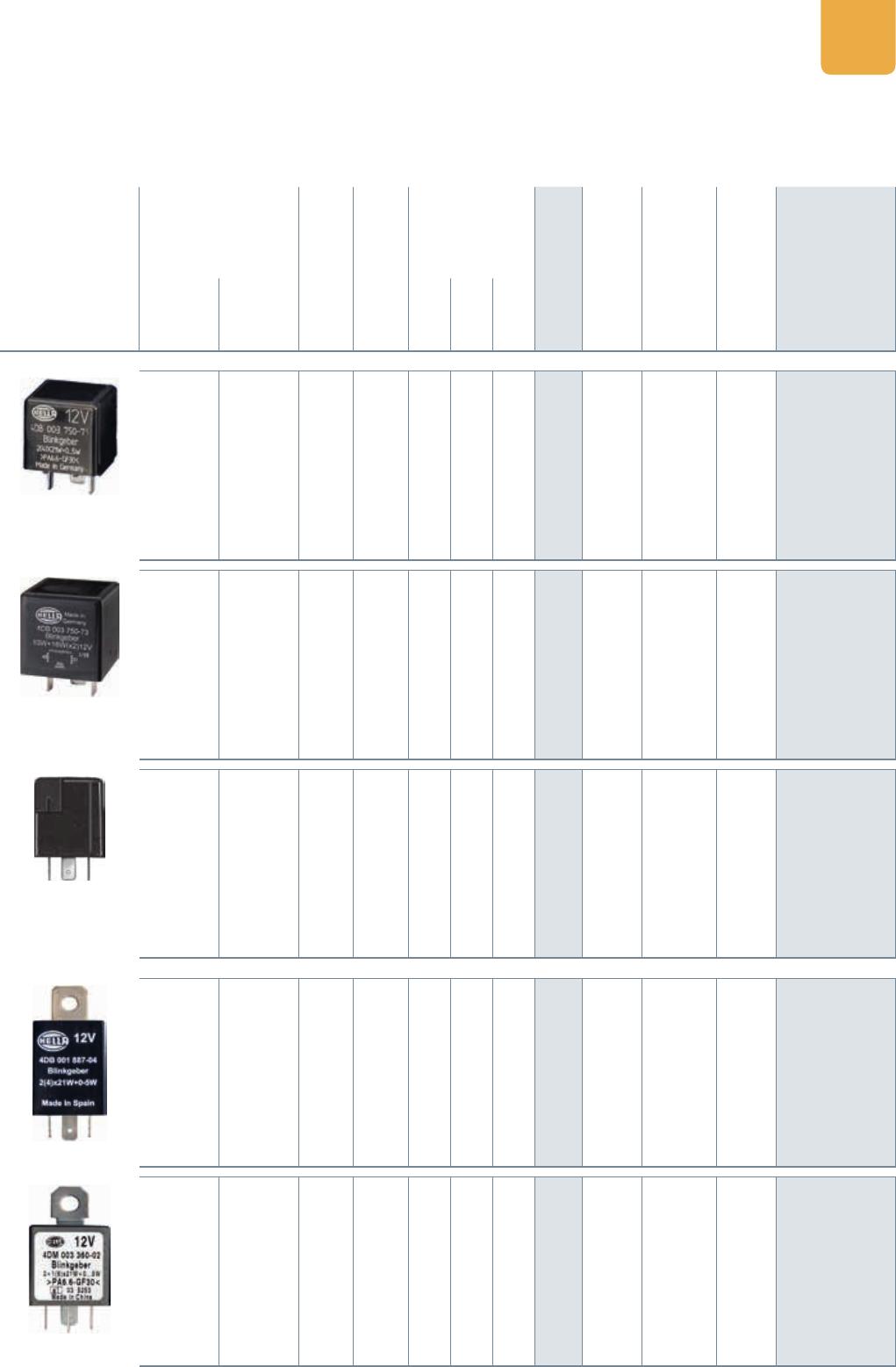

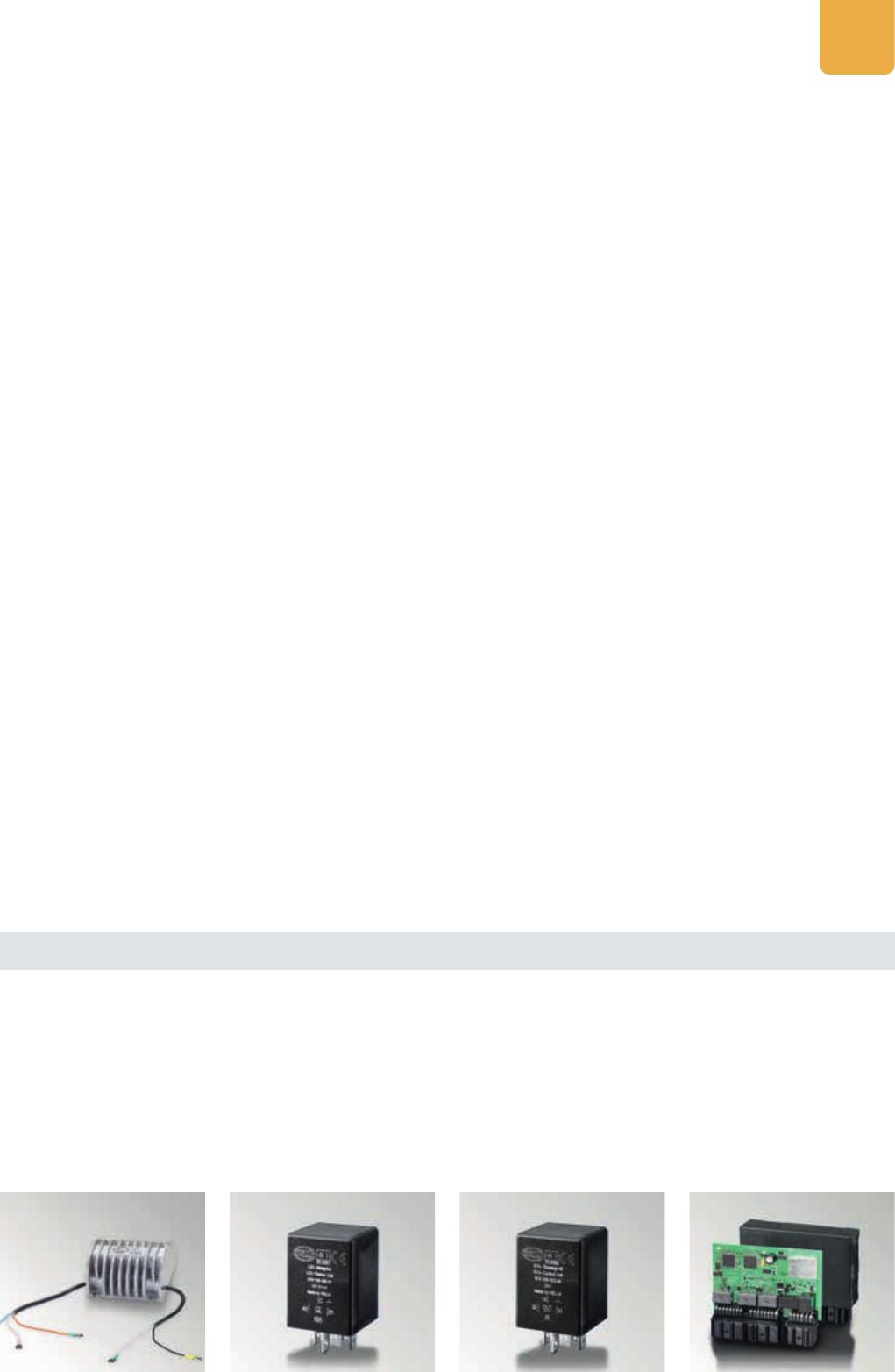

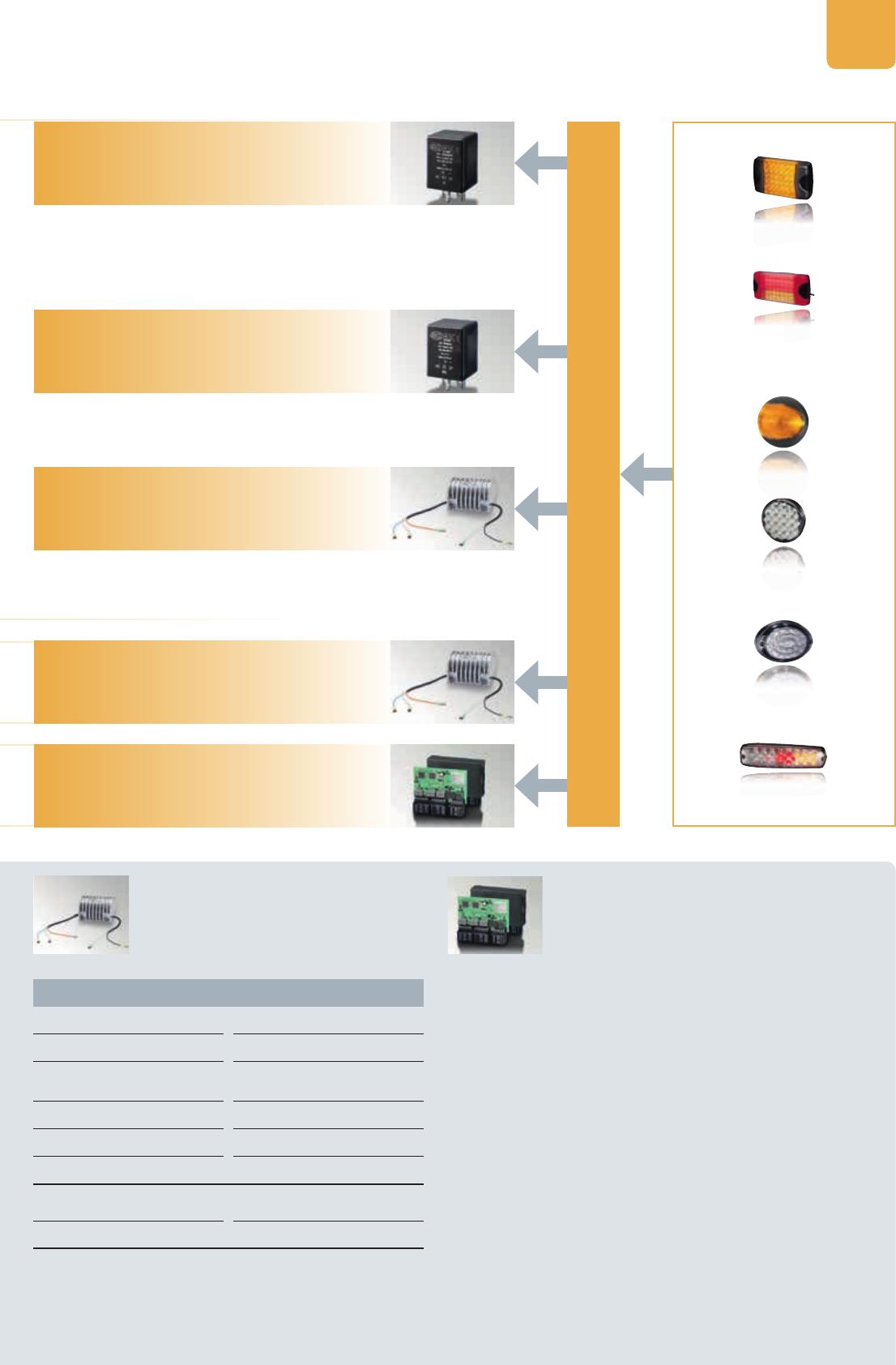

FLASHER UNITS 32

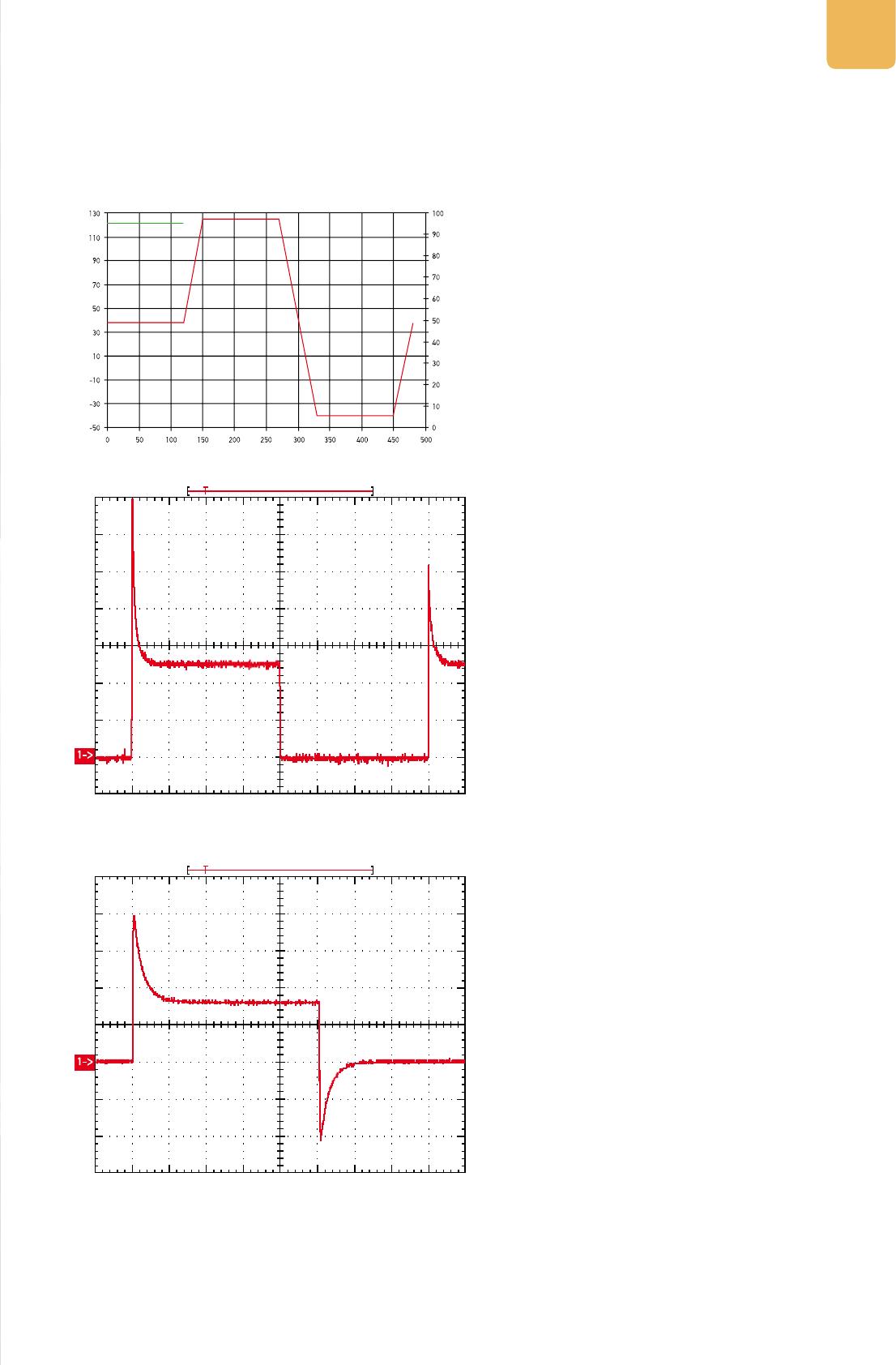

Explanation and uses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Test circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Flasher unit 6V, 4-pole and 12V, 3-pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Flasher unit 12V, 3-pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Flasher unit 12V, 4-pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Flasher unit 12V, 5-pole/6-pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Flasher unit 12V, 6-pole/7-pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Flasher unit 24V, 3-pole/4-pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Flasher unit 24V, 4-pole/5-pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Flasher unit 24V, 6-pole/7-pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

Flasher unit 24 V, 11-pole and 12/24 V, 6-pole . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

LED fl asher unit 12/24V, 3-pole; 12V, 4-pole/5-pole and 24V, 4-pole . . . . . . . . . . . . . . . . . . . . . . . .47

Overview of fl asher unit technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Legal regulations for fl asher units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

LED indicators and failure control from HELLA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

The right solution for your vehicle electronics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

WASH/WIPE INTERVAL CONTROL UNITS 52

Explanation and uses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Wash/wipe interval control units 12V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

Wash/wipe interval control units 24V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Headlight cleaning system 12V/24V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

CLOCK RELAYS 58

Explanation and uses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Clock relays 12V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Clock relays 24V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

ACCESSORIES 62

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

SWITCHING AND PLUG MATRICES 64

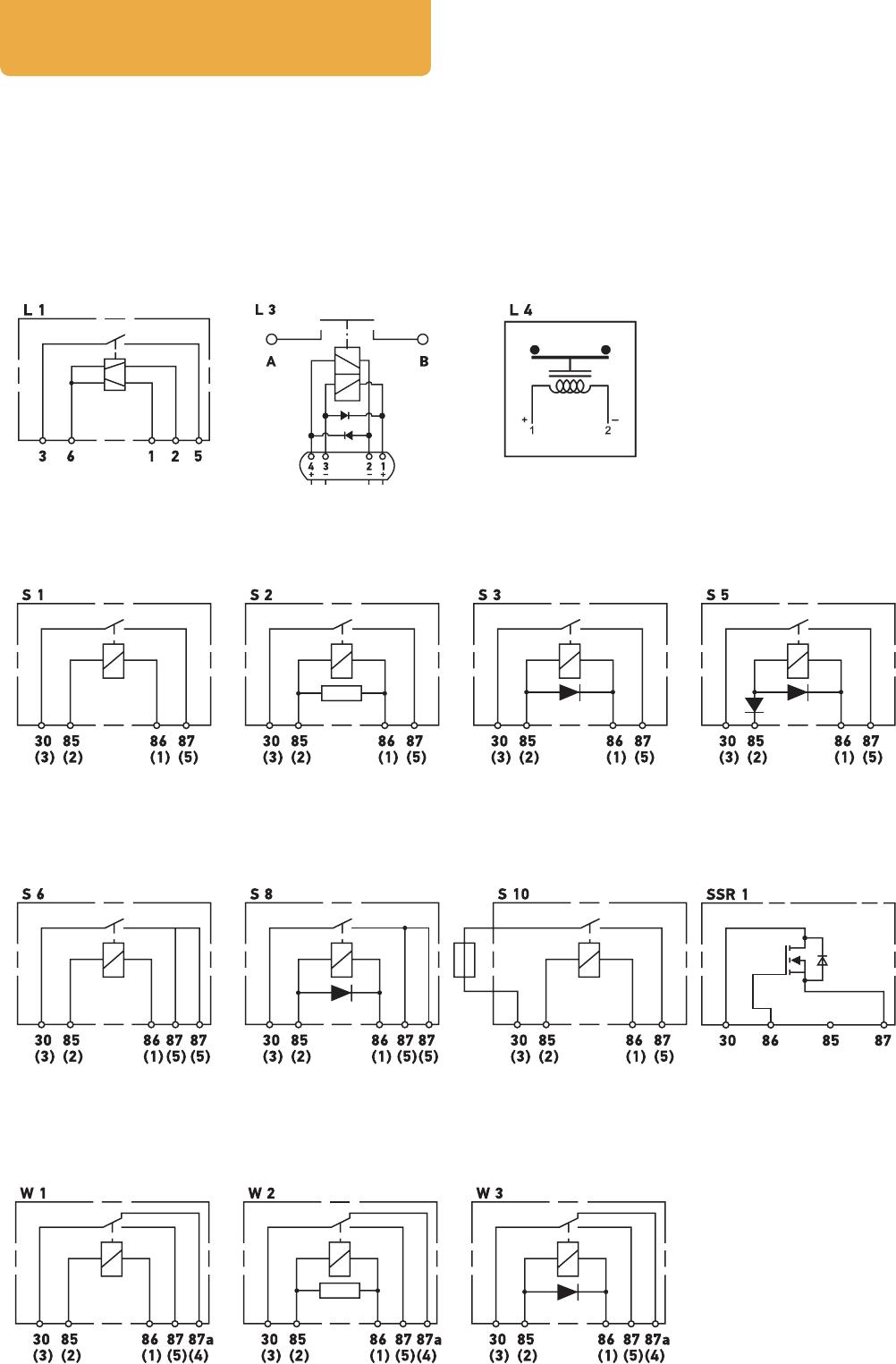

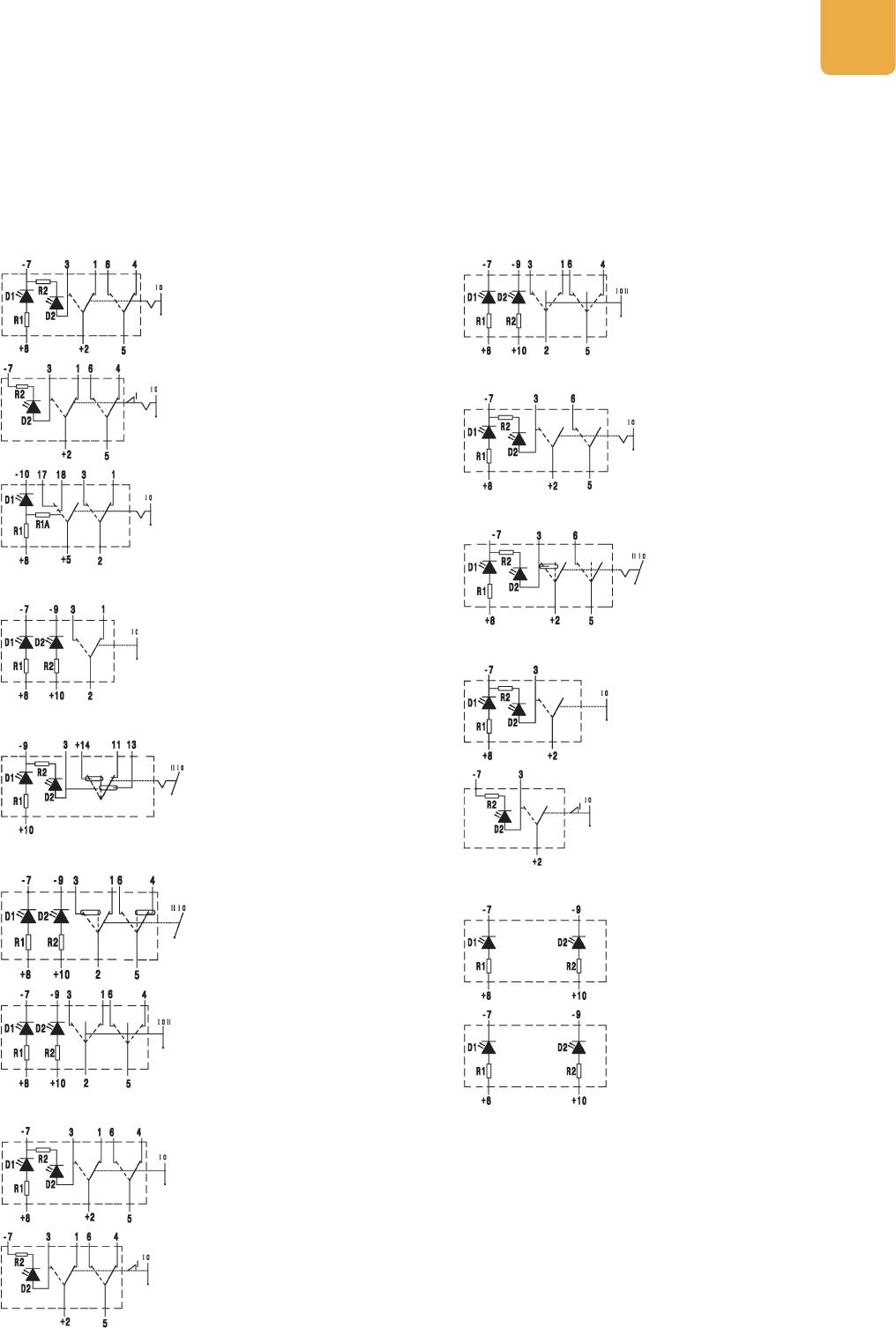

Circuit diagrams – electromechanical relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

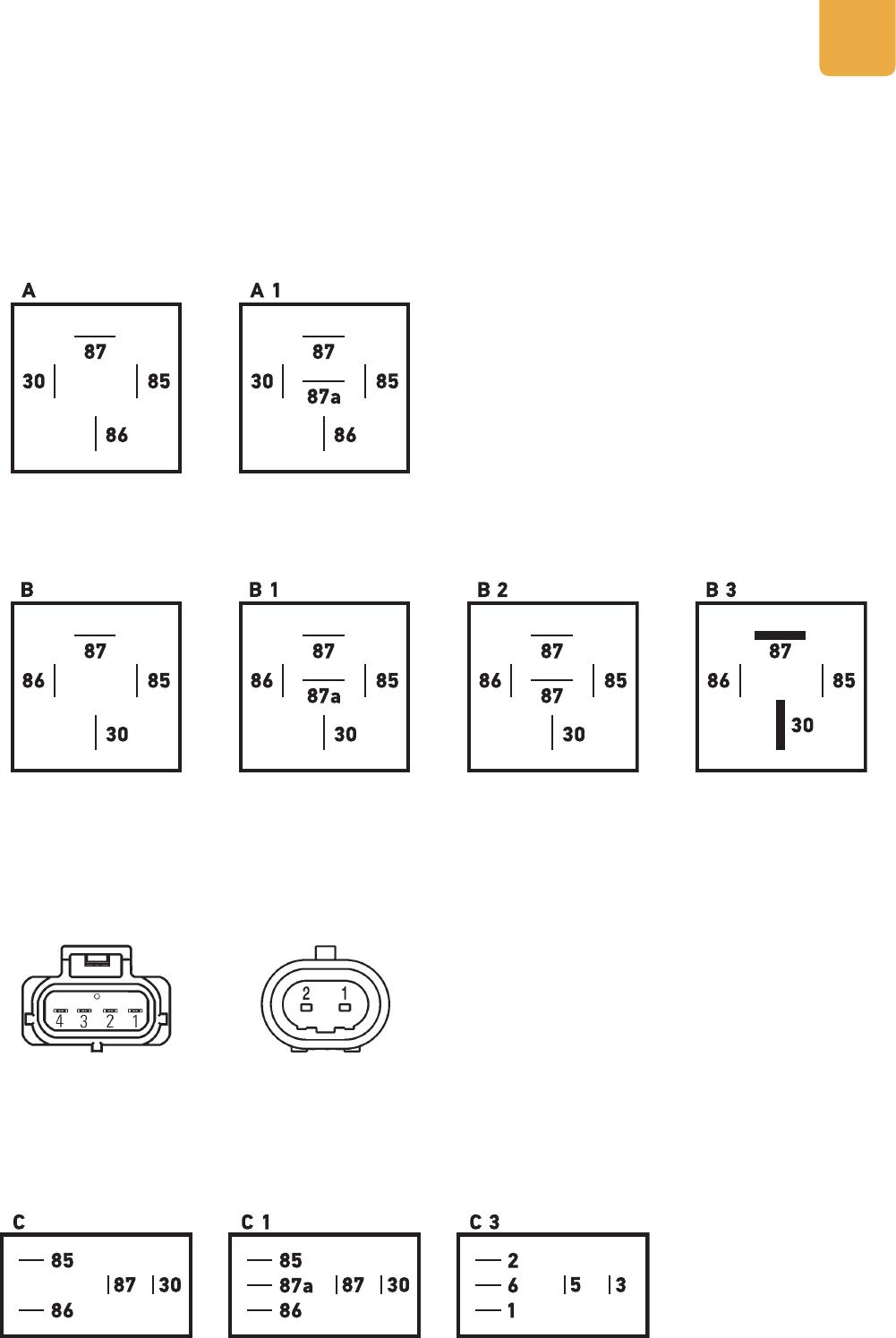

Pin diagrams – electromechanical relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

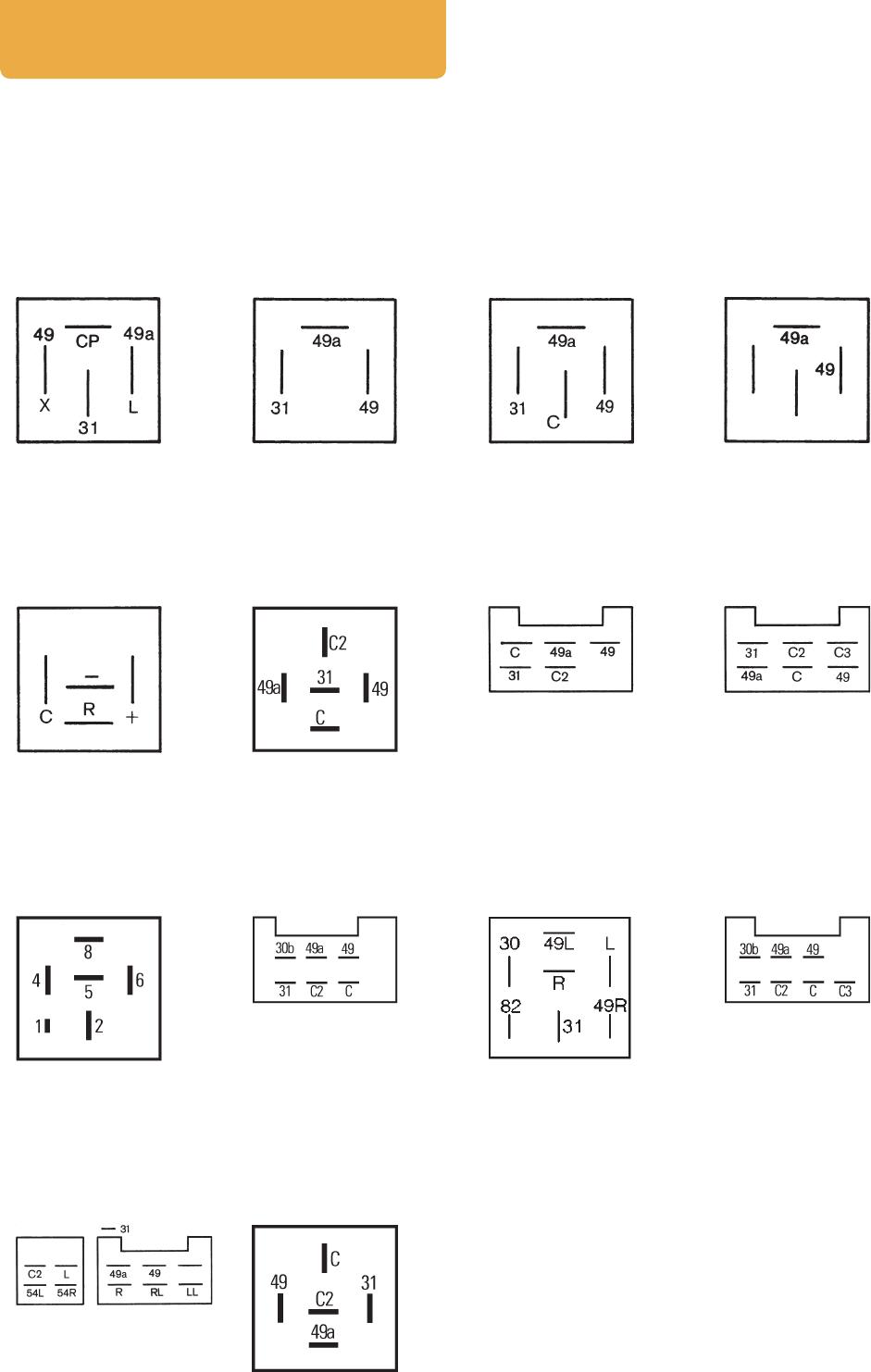

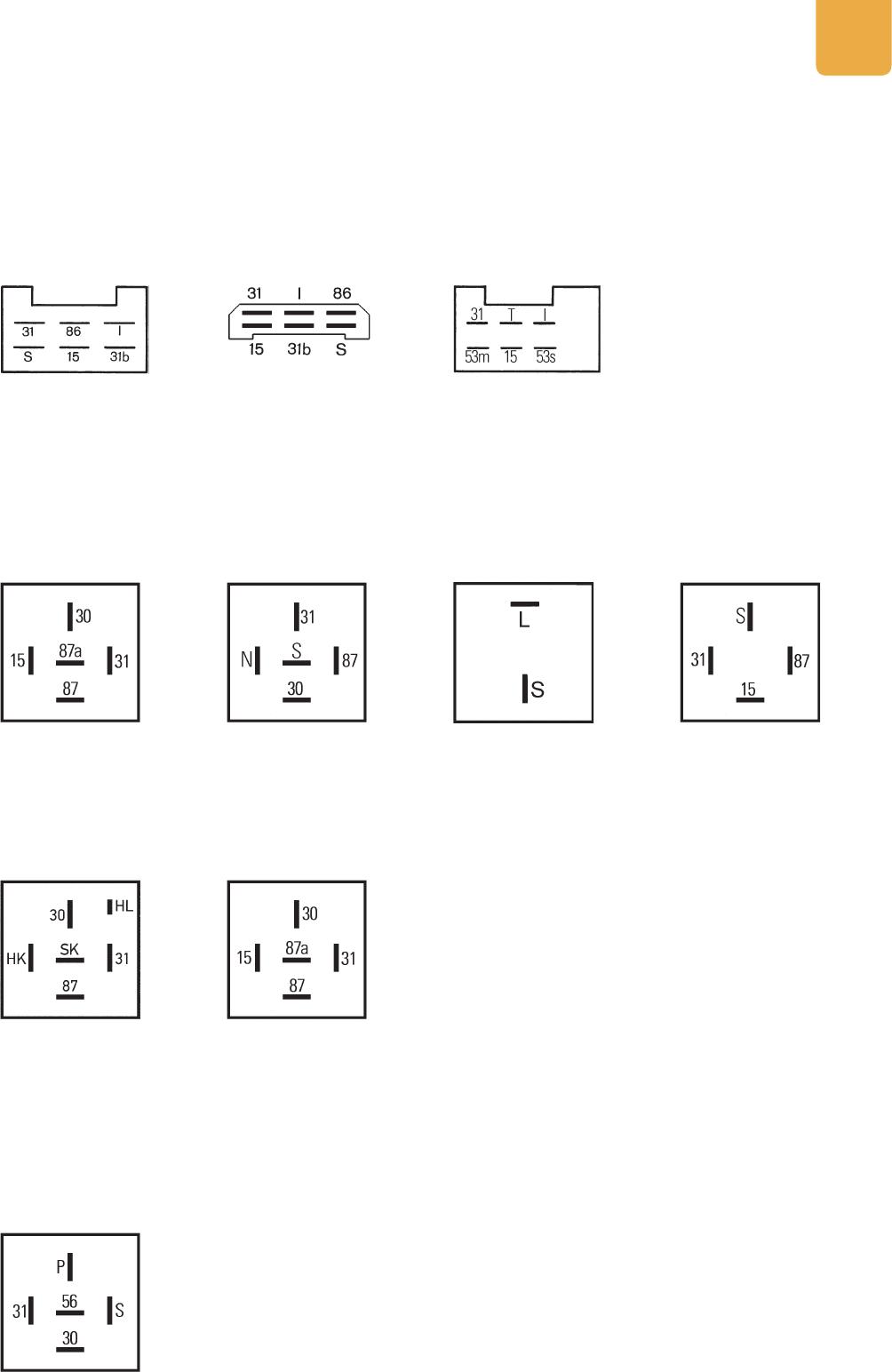

Pin diagrams – fl asher units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Pin diagrams – wash/wipe interval control units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Pin diagrams – clock relays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Pin diagrams – control units for headlight cleaning systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

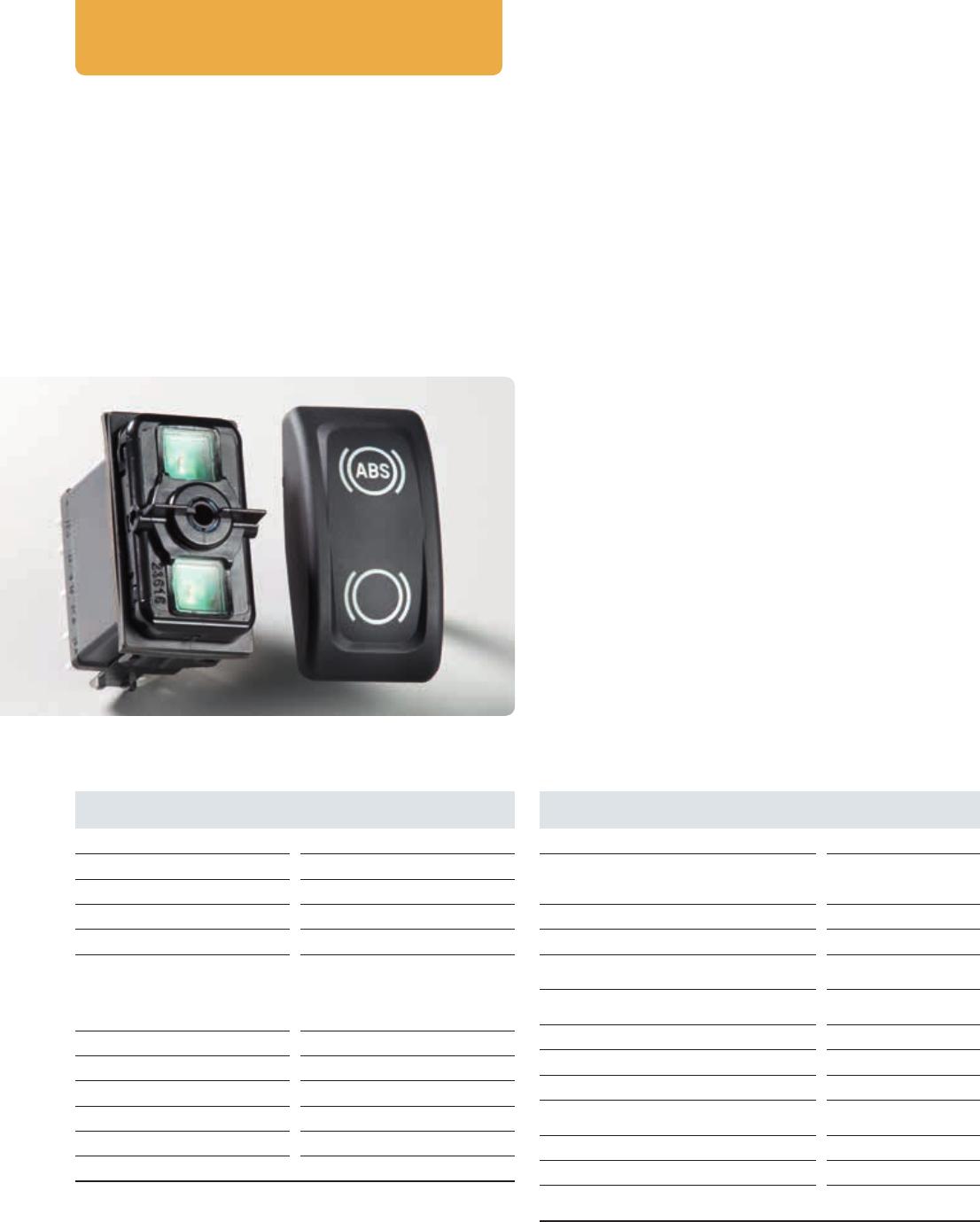

HELLA ROCKER SWITCHES 68

The new HELLA switch confi gurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Rocker switch, 3100 series. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Switch functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71